Shoudn’t it be 25%?

Current is not controlled here, resistance (aka the soldering iron) and voltage are.

Power = Voltage ^ 2 / Resistance. Double the voltage, that quadruples the power. So you only want to plug in iron 25% of the time to get equivalent power as 120V.

But it might not melt at double power? Maybe the extra heat helps, I can’t find a resistance/temperature curve for a soldering iron…

Source: EE dropout.

nnnNNEEEEEEERRRRRRRRRd!

Right you are. Oops.

If only the oop was here to see this 😔

What are you lookin at

In my defense, I’ve been helping a friend with an EVSE install where the load (electric vehicle) is smart. In that context, it’s just voltage X current capacity of the line = power. The rest of the story is true as far as I know.

I sure hope someone will be fired for this obvious blunder

Ok. I was acountless on lemmy for a long time, your comment made me finally register. Thanks!

So, yeah, with double the voltage you get 4x the power. But you you put 4 times the power at 50% of the time, you get only 2x the power. And the other half of the time, you get 0 power. On the average you get the same power output.

You double counted there.

You said 4x power 50% of the time and then said “the other half of the time.”

So you’re calculating 50% of 50% which is 25% duty cycle.

Oh no, I didn’t. Should I draw a graph? Pop out some equations?

Let’s say P is the nominal power. When I said “The other half” I meant when the solder iron is not plugged. So:

50% of the time at 4xP 50% of the time at 0…

Oh shizzzz, you’re right!

I imagine this is more or less what it felt like to be in the room at the time. A whole group of people discussing electrical theory and optimal soldering techniques and meanwhile the one guy standing there holding the actual device notices the power cord is a little loose and pushed it in another 1/8" without mentioning it because everyone is so involved in their nerdy conversation.

Also, welcome to Lemmy!

I had to think about it too, lol. This is an equation for DC/instantaneous power, and if you want to get into AC math, this is more like a square wave. Averaging the power out doesn’t necessarily work like that, as you figured out, as it doesn’t when you try to measure AC (sinusoidal) power by peak voltage or whatever.

There are gas powered soldering irons that are essentially lighters with metal around the flame. Real life savers

There are also battery powered soldering irons.

I like the pinecil, usb-c powered soldering iron with temperature control. If you are not doing anything intensive any fast smartphone charger will power it.

yes but that sounds boring and doesn’t require having a functionally super-hot piece right near a reserve of acetylene.

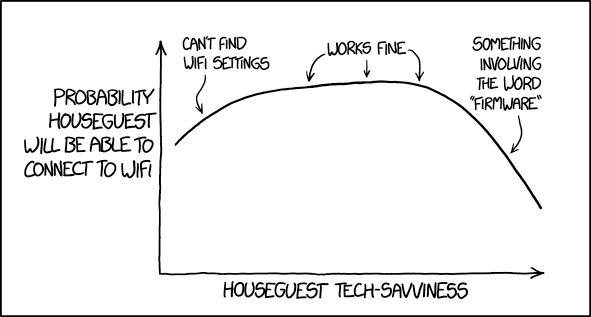

there’s the STEM bell curve. XKCD shows the axes as ‘how well your computer works’ vs ‘how well you know computers’. that is accurate.

but if you’ve ever known serious engineers who didn’t just live boring white collar work-home-work-and-some-marvel-shit lives, you’ll have seen things that make this look mild.

I think there’s another one, where the right side references operating systems, and another without the graph that’s along similar lines. long runners sometimes return to the same wells, I guess.

Link?

no, sorry; I’m profoundly lazy.

well at least you’re honest

I have my incredibly rare moments. yes.

It’s only stupid if it doesn’t work

And vice versa

Yeah! “It’s only doesn’t work if it stupid.” 🤷♂️ I’ve always said that…

It’s only work if it doesn’t stupid.

Should have just left it in, and been able to get the soldering done twice as fast.

New manufacturing hack unlocked: Install 240v outlets at workstations and fire half of the workforce. Golden parachute and douchey, hand-wavey TED Talk, please!

Elon knows more about manufacturer than any other person on earth, he said

Don’t they have switches?

No.

Seriously, many soldering irons don’t have a switch. Fancy soldering stations have switches, temperature dials, etc. But basic ones are just a resistive load wired directly to the plug.

Sounds like a cheap portable soldering iron, which just heats up to some roughly usable temperature whenever it’s plugged in.

Ive seen some really cheap irons that have zero controls, you plug them in and they operate at max power. Basically a wood burning pencil, really.

An engineer that has a project to show off at a trade show will have will have both a power switch and a temperature control on their soldering iron.

I’m an engineer that’s been in that sort of situation. If it’s planned, you have the tools. Unfortunately, sometimes these things happen and it’s not planned. At that point it’s taken what you can get. A cheap fire stick will still do the job better than no fire stick.

Reminds me of the time when I helped install some 120 VAC ceiling fans and the electrician* wired them to the 220 VAC line. They spun like a helicopter trying to take off.

*Worked for the local electric utility, we trusted him, foolishly.

They need a 1/4 duty cycle.

Finally, an usecase for USB irons!

I just got one, and it’s so practical with a PD battery bank. Can now solder inside or outside on my car/bike with zero hazzle

I love my Pinecil. I recommend them to kids as a beginner iron cause of the low price and sleep function.

I have one too, I like the idea of it but can’t solder with it. For any serious work I use my old transformer iron that has enough power to melt the solder.

Sure, a Weller station will probably last a lifetime even with serious usage, but I do maybe…. 20 total solder joint per year, so I couldn’t justify the price.

I do agree that it’s better at what it’s supposed to do though

Not quite a Weller station, but also will last a lifetime ;)

Edit: I’m aware that USB irons are good and I’m just shit at using them

I really appreciate that you took the time to take a photo to show us your iron. It’s nice to get the more personal touch as I keep forgetting we are real people talking together.

It looks like an old clenodium. I’m sure it has seen its fair share of work. Thanks for sharing!

I had the opposite problem, I brought a soldering iron from Europe to Canada, and despite using a step up transformer, it just couldn’t get hot enough to melt the solder!

You should have used 200% duty cycle

Splice on a second plug, so you can use two outlets at the same time.

(/s, mostly… this can actually work, if you can find two outlets on opposite phases.)

There’s an actual commercial product that does this. It even meets UL and CSA standards.

But it wouldn’t be 200%, it would be something like 170% power assuming 3 phases, right. Too lazy to do the math.

You’re correct, phase-to-phase is 173.2% of the phase-to-neutral voltage in 3-phase “Wye” service.

But that’s not what consumers (typically) use in North America. We don’t bring three phase to the home.

Our single-phase final distribution transformers have a center tap on the secondary coil, bonded to neutral. So, one side of the coil provides a 120v leg with respect to that neutral, and the other side provides an opposing leg, 180° from the first, and 120v with respect to that same neutral. Most of our appliances use leg-to-neutral, 120v. But leg-to-leg is 240v.

(Commercial and industrial facilities can get a wide variety of voltages in single or three phase, and we do have some actual, 2-phase generators and customers: the phases are 90° apart rather than 120° or 180°)

I’ve had a similar experience as a child. I live in Germany and found this voltage switch on a hair dryer. My thoughts were like: Switching it to less couldn’t possibly hurt, could it? Well it could. It was super efficient though but only for a few seconds before it self destructed.

Person Wait Modulation.

Hey. If it works, it works.

Any port in a storm right?

Sounds super safe.

Because the plug would fit the outlet, right?

There are a bunch of adapters you can buy that don’t convert voltage, and it’s pretty common for people to buy them by mistake.

If someone knows how to solder, a different shaped plug isn’t a big obstacle to them