I’ve been noticing an unsettling trend in the 3D printing world: more and more printer manufacturers are locking down their devices with proprietary firmware, cloud-based software, and other anti-consumer restrictions. Despite this, they still receive glowing reviews, even from tech-savvy communities.

Back in the day, 3D printing was all about open-source hardware, modding, and user control. Now, it feels like we’re heading towards the same path as smartphones and other consumer tech—walled gardens, forced online accounts, and limited third-party compatibility. Some companies even prevent users from using alternative slicers or modifying firmware without jumping through hoops.

My question is: Has 3D printing gone too mainstream? Are newer users simply unaware (or uninterested) in the dangers of locked-down ecosystems? Have we lost the awareness of FOSS (Free and Open-Source Software) and user freedom that once defined this space?

I’d love to hear thoughts from the community. Do you think this is just a phase, or are we stuck on this trajectory? What can we do to push back against enshitification before it’s too late?

(Transparency Note: I wrote this text myself, but since English is not my first language, I used LLM to refine some formulations. The core content and ideas are entirely my own.)

Many people don’t care about FOSS or don’t know the benefits, they just want a NOW working product. Many belief in the goodness that nothing bad will happen, and if something happens, they still can switch. I often have this discussion with other colleagues and friends, it’s an endless debate of price , features , comfort and support. As long as there is both on the market , why argue? People can buy what fits their needs.

My opinion on bad manufacturer behavior is: if we keep buying those products(with locked down firmware, Windows-Only Proprietary Cloud filled forked Slicers etc.) more and more manufacturers may go that route.

The problem is people’s stinginess. They want to save money and buy from China. The manufacturers help themselves to the OSS community but do not contribute anything - on the contrary, the manufacturers undercut the OSS alternatives enormously. They have no development costs or anything else to compensate. So that the OSS solutions do not finance the development for other companies and push themselves out of the market, the only option is to lock it in. It’s the people who want to get into an expensive hobby on the cheap.

Edit: example about developing stats.

PrusaSlicer

PrusaSlicer is our own open-source in-house developed slicer software. The PrusaSlicer team consists of 13 full time developers. As of January 2024, we spent a total of 145,720 work hours developing PrusaSlicer (that’s over 16 years of non-stop work by one developer). While only about 10% of the original code remains, we are still extremely proud that PrusaSlicer is originally based on the open-source project Slic3r by Alessandro Ranellucci. Each of the source files has a short header with the list of all contributors. We believe this is the right way to acknowledge whose shoulders we’re standing upon.

PrusaSlicer is a completely free, feature-rich, frequently updated tool that contains everything you need to export the perfect G-code for your 3D printer. Today, the PrusaSlicer code powers most slicers on the market.

Prusa is based in Prague, and according to some quick googling the average software developer in Prague makes 88k CZK (~3800 USD or ~3500 eur), so about 526 CZK/hr (~22/hr in both USD and EUR).

Which means they’ve potentially spent around 76.7 million CZK (~3.3 million USD, ~3 million EUR) into their slicer. Just for salaries.

I wonder if any of that includes what are essentially firmware tuning for their printers?

I recently ran a set of prebuilt Prusa M4S for a printing demo, and they were really nicely tuned, between the pressure sensing head and the way it only probes the area of the print bed it’s going to use, all 10 printers worked pretty much out of the box. One roll of filament wasn’t sealed properly and clogged a few times, but I basically did around 800-900 hours of printing over the course of a week and had a couple clogs from that one roll.

I wish I could have kept one, but my OG ended 3 is still hanging in there.

Just wondering, is this “trend” you’re talking about just the Bambulab situation, or are other manufacturers doing the same? I’m not super up to date on 3d printing news, so not sure if i missed more such changes.

If it’s the bambulab situation, it’s not entirely unexpected. When they started people were already worried about exactly this seeing how closed their ecosystem is. Then again, they did make a printer that just works better than the competition, and that’s in the end what attracts users.

Personally i have diy 3d printers that i built myself, really happy with them, but for people who just want to print things, many other filament printers are just too annoying to work with. Not everyone is into diy, and many people just want to make cool stuff and not care about the printer, and bambulab really made the next step towards achieving that.

So if the open source community wants to compete with that, they must make printers that are as user friendly. My diy 3d printers are like running linux. Really great and customizable if you like to work on 3d printers, and really reliable now i as an expert built & tuned them. But most people just want to buy a machine that works, and that’s not these open source printers. And as long as we just focus on making 3d printers for expert diy’ers, we’ll end up in the same place as linux is for OS’es: used by experts and for specific advanced usecases, but beyond reach for the common user that’s then stuck on systems like apple/windows that are more locked down, but actually just work without having to understand how the entire thing works.

I think you make some good points.

We have a old, self built Creality at work that is modded extensively and I love printing with it, but at home it just wont fly. The missus wants to turn the machine on, send over the G-code and pick up nice things later. There is no point trying to convince her to spend hours and hours learning input shaping, filament drying temperatures or the upsides/downsides of dual gear extruders.

People are pissed at Bambu, and rightfully so, but for home users where the crowd needing pleasing is not super tech-savvy, Bambu is just a great alternative.

I think we need to stop looking at it as Bambu fucking up 3D printing. They are massively increasing the reach of FDM for people who just want stuff to work without putting in the hours, while the rest of us can keep using whatever we want, be it OSS or not.

Hopefully with the increase in users, the selection of filaments and third party upgrades will increase too.They are the only reason I was ever allowed to have a 3D printer in the house, which has already opened her up to letting me get a RatRig in the future. You know, because two printers are obviously twice as fast as one (!)

Besides the others that were mentioned, Prusa is moving away from open source.

https://hackaday.com/2024/11/20/with-core-one-prusas-open-source-hardware-dream-quietly-dies/

I think there’s some semantic confusion with that article. That’s not what I see. There are literally kits for sale on the Prusa Site to convert your old prusa into a new Core. imho, What the ‘RepRap Open Source folks’ mean is literally every part is sourced from already available parts or can be printed. And I think this is where the article is going. The other Open Source -is Open Ecosystem. Where there may be proprietary pieces (the steel cage), but nothing about it is purposefully closed. Prusa published the full electronic and hardware schematics before the machine was shipping. https://www.prusa3d.com/page/open-source-at-prusa-research_236812/ This is also ‘Open’. Both are good. Both have valid rationale. But neither is anything like closed source, closed box, only we can touch it companies models.

Hard disagree. Prusas used to be completely open source. Now they merely have open source components. It isn’t accurate to call them open source.

Would you call Windows or MacOS open source? Both Microsoft and Apple have made parts of their OS’s open source, but that doesn’t mean the entire product is open source.

Anycubic for example does similar things. The Kobra 3 & Kobra S1 support Network printing(via Cloud) only through there “Anycubic Slicer Next” which is a Orca Slicer Fork only available for MacOS and Windows(Windows seems to be the only up-to-date Version, Mac is broken as far as i know).

Firmware is, as far as i know the so called KobraOS, a Klipper-go fork without a Webfrontend or any way to connect to it through Orca, Cura, Prusa or else.

Haven’t heard much about that yet, indeed also sounds bad. But it’s anycubic so who cares :p.

But yeah, it’s indeed not the best trend. But it also up to open source to actually compete with this, and not just chase shiny features, but also usability…

It’s giving me serious pause when looking at things like the new Bambu printer

I really like my x1c, but I haven’t upgraded it’s firmware yet, and probably never will, because the local features are just too good. I know I can replace a lot of the bambu cloud features with octoanywhere, but I shouldn’t have to

I installed the X-plus firmware, switched to LAN mode, blocked WAN acess at my router and use Orca slicer and honestly, I’m pretty happy with the result. That doesn’t mean I’d give Bambu a second chance after their recent moves.

Apparently the h2d is crippled if you use offline mode. No cutter or laser support

This is what I was always afraid of. With the x1c they didn’t really take away any hardware features if you put it offline and so the trade-off was acceptable. But locking you out of the physical hardware that you’ve purchased is a whole new story. Kind of like the dishwashers that require an app to do a rinse cycle.

For what the h2d costs you can get an awful lot of printer from a different brand

Honestly, if I were in the market for another machine right now I’d be taking a hard look at building a Voron. I don’t WANT a project like that, but it seems like the best compromise in the quality and capability vs price compromise. I’m told they’re working on a 600mm³ model that may really tempt me when they finish.

I suspect an important angle, at least for Bambu Lab, is AI. That’s why they are selling printers with expensive Lidar units at a competitive price (the X1C). The Lidar data adds a key part to AI training sets: print outcome. They could use this to train more AI models to improve their own products. I believe this is why they are first pushing the firmware update to X1C models.

Despite this, they still receive glowing reviews, even from tech-savvy communities.

I mean, most people don’t care. How often do you see mainstream smartphone reviewers making a single mention of the insane amount of bloatware and spyware on phones, or calling out Apple for their unrepairable devices? Shit just blows over eventually and consumers accept it for what it is. 3D printers are not exempt from this mentality.

Jeff Geerling made a video today about how he bought a dishwasher that was top-rated by

RTINGSConsumer Reports with no mention of the fact that in order to make it do a God damn thing, you have to connect it to the app, create an account, and connect it to them OEM’s cloud.Several years ago I bought a DJI action cam and it was the same thing. You can’t do jack shit with it without connecting it to an app and creating an account. I watched dozens of reviews and this was never mentioned. I returned it but I’m sure 99.9% either don’t give a fuck or accepted it.

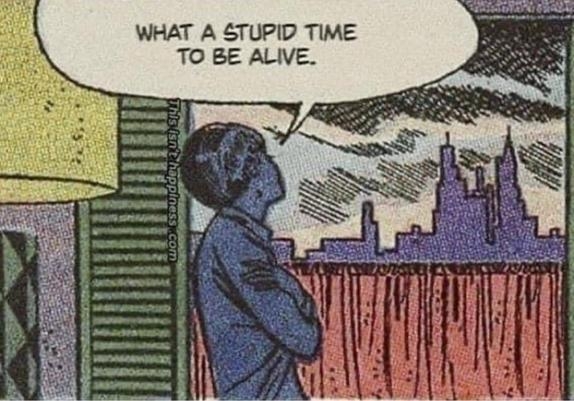

We have become so normalized to anti consumer behavior it doesn’t even matter anymore

Like it used to be that a videogame manufacturer charged for a dlc that was already on the game disc, you had to pay to unlock data that you technically had purchased but not licensed, and people threw a fucking fit. Now it’s like “this new tech device will only work if you insert $20 bills every 30 minutes” and people are like “oh well that sucks but what are you gonna do? I need a toaster that can send me a notification when my toast is done”

Fuck the companies that do anti consumer bullshit, fuck the youtuber dummies that normalize it because they got $50 and a free shitty printer, fuck the government that has completely failed to regulate anything, and fuck the dummies who constantly enable this nonsense because they refuse to spend 10 minutes researching their purchases and instead spend the rest of their life in credit card debt because they have $1100 in monthly subscriptions to stupid bullshit that makes their stuff work for 18 months until the company goes bankrupt, their device is bricked, and they replace it with another piece of shit that has the same anticonsumer bullshit

It’s just like everything else with technology. As soon as the “normies” start buying into it everything goes to shit. They don’t know what to look for and just buy whatever’s easiest. Once it gets that far the manufacturers can do whatever they want

All the Youtubers Bambu sponsors are like, “I was terrified of 3D printing. Wasn’t that something only nerds do? Then Bambu sent me a free 3D printer and several hundred dollars and I’m telling you guys, you don’t even need a brain to use it!!!”

I have a Bambu A1, and yes it really is a great printer. The firmware BS is crossing a line though, and that company will not get another dollar from me. My next printer will be a Prusa or a Voron.

I don’t understand why this is such a big deal. There is no huge open source scene for regular printers. Because it’s a tool, not a hobby. People want a print on paper and move on. This gatekeeping gotta go: It’s holding 3D printing back. Bambu did for 3D printing what Apple did for mobile phones: They made 3D printing clean, simple and easy. If you want to fiddle around with custom firmware and usability hacks and cobbled together components, power to you. I’ll be over here, actually printing things.

I build an original voron 1.0, reused the parts to build a 2.0, and built that into a 2.4 with mostly newer parts because the frame was just fucked from all that nonsense. I have a very low serial from back when they did that on the subreddit, not sure if that’s still a thing

Even with the raggedy frame it was a great printer. But building it properly it’s bulletproof. Costly but if you want a forever printer that you can mod it’s the way to go imo

My 0.2 Parts are on the way.

Thought about buying the upcoming Sovol Zero but i guess its the time to build my first Voron :)

Which kit? I’m finishing up mine soon.

Its mostly Fysetc but some other parts as well. I spend the first half of my day building but i make a break now to get some fresh air

Nice. I went Sibor with the CNC kit for an… odd reason? It needs to survive repetitive van transport.

Free systems were expensive, hard to use, and had worse finish

Bambu came, made a better [proprietary] product

People obviously bought it

Then other manufacturers saw that they could sell proprietary products just as well and jumped into the bandwagon

I love DIY.

At home, I run and build DIY printers but you can’t deploy them in a business/production. Why? As soon as there is a printer that isn’t it just works with easy (and documented) maintance procedures the business needs to hire not only a worker but a worker who knows 3D printers. That’s bad.

Printers like the Sovol SV08 and Biqu AMS (still not launched) aren’t just there yet.

Combined with the BambuLab pricing on the A1 mini and P1S it is pretty difficult to buy FOSS.

Prusa is close with the Core 1 but they don’t have an good AMS package for their printers (their MMU lacks a enclosure/easy to deploy setup). They propably know it but don’t have the answer avaible.

Equally on the econmics side it is difficult: The BambuLab P1S killed the (FOSS) market.

If I compare a 1150€ BambuLab X1C against the 1350€ Prusa Core One I would likley prefer the Prusa product/ecosystem. With the P1S it suddently is 700€ compared to 1350€ for a machine that will produce the exact same parts with a near identical cycletime, uptime and opperating/maintance cost. The decission in favor of BambuLab is easy.

False dichotomy. There are plenty of printers that are pro-sumer and also have great documentation and are easy to use and maintain.

Name one that is competitive to the BambuLab P1S combo.

Keep in mind that the operator is an average Joe, who knows nothing about 3D-printers, with minimal training on the job to do the maintenance.

Competitive (explicitly) includes cost: If I need to pay $2k for a printer that works just as well as an $800 option it is not feasible (for a business) to spend this much more.

I could but I’m going to assume that you already know and will simply disagree.

Tell me.

Looked last week into it and concluded that BamubLab is still the best option.

Runner up was Creality. They are equally proprietary these days.

How is Creality equally proprietary? I can put mainsail or fluidd on the machine and use any slicer I so choose.

So your suggestion would have been the Creality K2 or K1C?

I own a BambuLab A1M as I want a printer that just works. And while yes it is all proprietary they do sell replacement parts for most parts.

While I will not forgive them for their latest moves I am quite happy, I turn it on, load an stl into BambuStudio and let it run without any issues at all.

My next printer will however probably be a prusa as they are Europeans and I love that they keep everything up to the user so far. But I can not deal with anything that is more DIY than a Prusa, it is a tool for my hobby…not the hobby itself.

they do sell replacement parts for most parts.

If you can’t replace all of the parts with some other off the shelf part, regardless of quality, then you’re locked to a brand and are at their mercy.

What happens when they inevitably discontinue the A1M and no longer sell parts for it?